Why Choose CHUMPOWER L Series for PET Bottle Production

Looking for a smarter, energy-efficient PET stretch blow molding solution?

In today’s packaging industry, energy efficiency, lightweight bottle design, and smart automation have become the foundations of modern PET bottle manufacturing.

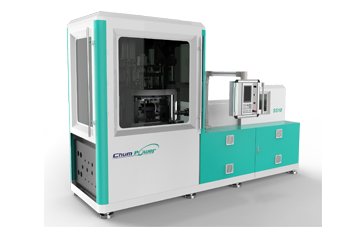

CHUMPOWER MACHINERY CORP., Taiwan’s leading PET stretch blow molding machine manufacturer, presents the L Series Linear PET Stretch Blow Molding Machines — an all-electric, high-performance solution designed for medium to high-output production lines.

This guide explores the core features, model comparisons, and real-world applications of the L Series — helping you choose the right system for your production goals.

Key Features of the CHUMPOWER L Series

The L Series offers wide capacity coverage (60 mL–20 L), all-electric servo efficiency, up to 35% energy savings, and full smart factory integration for modern PET bottle production.

-

Wide Capacity Range & High Output

- Supports 60 mL to 20 L bottle sizes

- Delivers up to 24,000 BPH (bottles per hour)

- Ideal for water, edible oils, beverages, sauces, cosmetics, and pharmaceuticals

-

All-Electric Servo Drive System

- Equipped with German BECKHOFF multi-axis controller

- Synchronizes complex motions and boosts production efficiency

- Improves speed by 10% over pneumatic systems

- Delivers quieter, cleaner, and more stable operation

-

Energy Saving with Air Recovery

- Reuses high-pressure air for mechanical functions

- Optimized infrared heating system

- Achieves 30 – 35% energy savings vs. traditional linear machines

- Reduces operating costs and carbon footprint

-

Lightweight Bottle Optimization

- Unique neck protection design prevents deformation

- Independent neck cooling ensures consistent clarity

- Enables up to 20% bottle weight reduction without compromising strength

-

Smart Factory Integration

- Compatible with BottleViewer management system

- Real-time monitoring of production, energy use, and OEE analytics

- Multi-user dashboard for data-driven decision-making

- Supports digital manufacturing and Industry 4.0 initiatives

L Series Model Comparison

| Model | No. of Cavities | Max Bottle Size | Application Focus | Max Output (BPH) |

|---|---|---|---|---|

| CPSB-LS | 1–12 | 60 mL–20 L | General-purpose, high-output lines | 24,000 |

| CPSB-L2G | 2 | 12–20 L | Large water & oil bottles | 約 9,000 |

| CPSB-LL2M | 2 | Up to 6 L | Special shapes, fast mold change | 約 8,500 |

| CPSB-LSS12 | 12 | Up to 0.6 L | Small-bottle mass production | 24,000 |

| CPSB-L4M / LL4 | 4 | 3–6 L | Versatile mid-size production | 11,700–22,400 |

For full technical specifications, visit the CHUMPOWER L Series Product Overview.

How to Select the Right L Series Model

- High-volume beverage production? Choose CPSB-LS or LSS12 for scalable output.

- Large format bottles (5L-20L)? Opt for CPSB-L2G with reinforced blowing precision.

- Frequent mold changes or special shapes? The LL2M model features side heating and fast eject systems.

- Maximum efficiency on smaller formats? Go for LSS6 or LSS12H with 0.6L support.

Real Applications — From Bottled Water to Cosmetics

The L Series is trusted worldwide in:

- Mineral water production

- CSDs, juices, and tea beverages

- Cooking oil and sauces

- Cosmetics and pharmaceutical packaging

Its versatile bottle compatibility and intelligent modular design enable flexible adaptation across FMCG, healthcare, and industrial packaging industries.

Final Thoughts: Upgrade to Smarter, Leaner PET Blowing

CHUMPOWER’s L Series is more than a blow molding machine — it’s a future-ready production platform.

With robust servo control, air-recovery efficiency, and smart-factory connectivity, the L Series helps manufacturers cut energy use, improve uptime, and achieve sustainable, data-driven PET production.

The CHUMPOWER L Series provides an all-electric, energy-efficient solution with advanced automation, covering bottles from 60 mL to 20 L. It supports global manufacturers aiming for higher output, lightweight design, and sustainable operation.

FAQ — Common Questions About CHUMPOWER L Series

Q1: What makes the L Series different from other PET blow molding machines?

A1: The L Series is fully electric, combining servo precision, 35% energy savings, and smart factory integration for greater efficiency and stability.

Q2: Can the L Series handle different bottle sizes?

A2: Yes — it supports a wide range from 60 mL to 20 L, suitable for water, beverages, oils, sauces, cosmetics, and pharmaceuticals.

Q3: How does the L Series help reduce energy consumption?

A3: Through air-recovery technology and an optimized infrared heating system, saving up to 35% compared with conventional machines.

Q4: Is the L Series compatible with smart factory systems?

A4: Absolutely. It connects with BottleViewer for real-time monitoring, energy tracking, and OEE analysis — empowering digital transformation.

Q5: Which model should I choose for 5-liter bottles?

A5: The CPSB-L2G model is ideal for large formats like 5 L – 20 L bottles, ensuring stable blowing precision and strong structural performance.

Call to Action

Ready to upgrade your PET bottle production?

CHUMPOWER offers customized consulting, system integration, and full OEM/ODM solutions for the L Series.

Contact our team today to receive tailored recommendations and production optimization guidance.