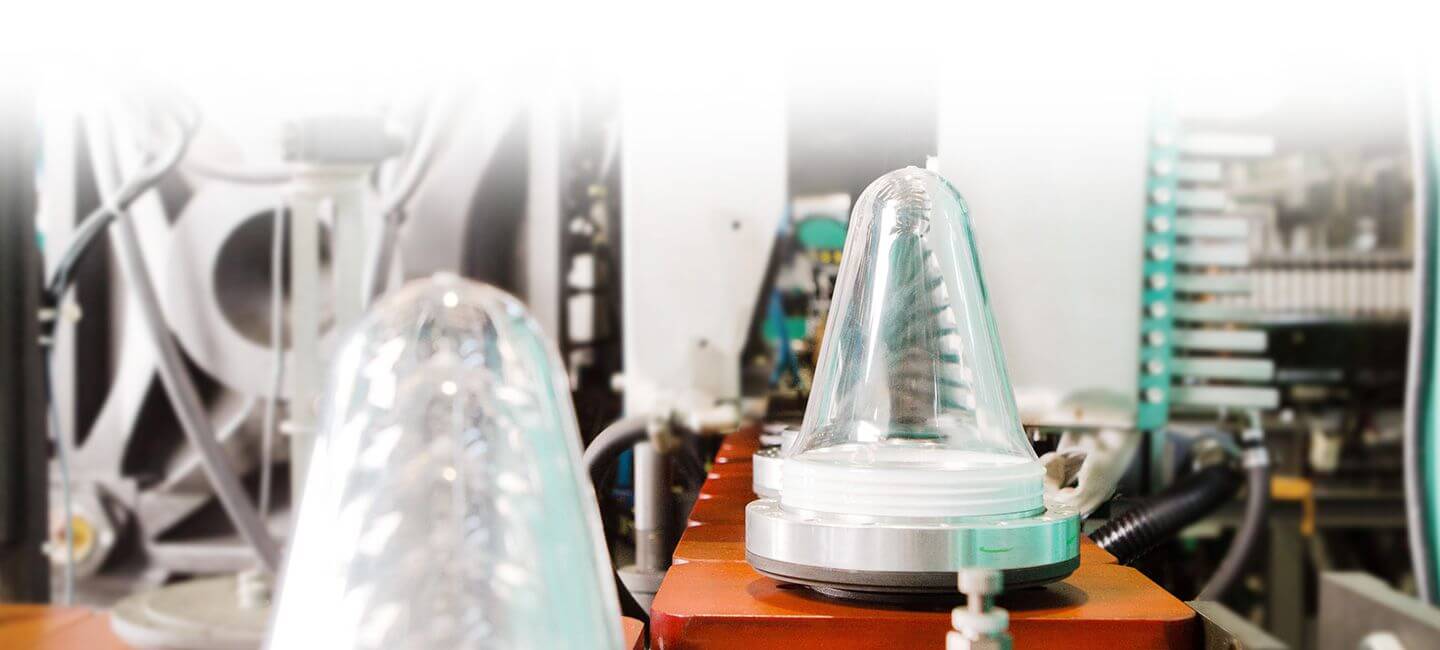

One-Stop ServicesMolds, machines, production lines, CHUMPOWER has everything you need.

Most Reliable From frigid zone to tropics,CHUMPOWER machines are operating all over the world.

Best Services More than 1200 personnel visits in Global Aftersales Services

Mold Modeling and Designing We have mold experts with over 20 years of experiences. There are no bottle molds that we cannot handle.

Mold Modeling and Designing We have mold experts with over 20 years of experiences. There are no bottle molds that we cannot handle.

Cloud-based Bottle Type DesignThrough our cloud designing platform, clients can complete the blow molding designs online.

Energy Saving ModelsGas recycling, high efficiency ovens ensure cost savings and environmental protection.

With over 40 years of history, CHUMPOWER is the largest PET stretch blow molding machine manufacturer in Taiwan, and the CHUMPOWER PET stretch blow molding machines made in Taiwan are running steadily in 115 countries. We can provide a comprehensive range of services, be it molds, production machines or full production lines, CHUMPOWER offers the best solutions.

Our clients are spread across the world. Even in the harshest climates (frigid zone or tropics), CHUMPOWER machines can maintain stable operations. At the same time, we have an extensive before sale and aftersales team that can offer 1200 personnel visits in global aftersales services to ensure the optimal protection for your machines.

Our development team has more than 40 years of experiences, can reach any requirements for every individual case. Regardless of whether the product is used for beverages, water, cooking oil, daily products, or cosmetics, CHUMPOWER machines can help you to achieve PET bottle production for every type of capacity.

In the past few years, CHUMPOWER has been produced thousands of molds with different specifications. We have experienced teams, and invested large capital in constructing a mold production center. When combined with the carefully selected high-quality materials and our stringent quality control, the molds manufactured will have outstanding quality and precision, and come in different shapes. We have also established a cloud-based mold-designing platform so that you will be able to complete your design with our mold specialists through the internet!

PET is a well-known eco-friendly packaging material that has high recycling rates, and we are committed to improving the energy conservation rate of the machines. Through methods such as gas recycling and high efficiency heating ovens, higher efficiency can be achieved with less energy, enabling you to save costs and join CHUMPOWER as an Earth-friendly green enterprise.

We are not only PET expert, also your best business partner in PET systems.

-

2024● At TaipeiPLAS, the CPSB-LL2M, a two-stage stretch blow molding machine capable of using 100% rPET, won the Gold Medal in Blow Molding Machines and the Excellent-Intelligent Machinery Award.

2024● At TaipeiPLAS, the CPSB-LL2M, a two-stage stretch blow molding machine capable of using 100% rPET, won the Gold Medal in Blow Molding Machines and the Excellent-Intelligent Machinery Award.

● Officially began preparations for the compilation of the Sustainability Report. -

2023● With guidance from the Precision Machinery Research & Development Center (PMC), CHUMPOWER initiated its greenhouse gas inventory.

2023● With guidance from the Precision Machinery Research & Development Center (PMC), CHUMPOWER initiated its greenhouse gas inventory.

● The Taiwan Association of Machinery Industry (TAMI) hosted an Industrial Digitalization and Lean Management Demonstration Event at CHUMPOWER's Wuri headquarters. -

_pic.jpg)

2022● At TaipeiPLAS, CHUMPOWER unveiled the SS10-rPET one-stage injection stretch blow molding machine, capable of producing bottles from 100% rPET. The machine won the Excellence Award in the Plastic Hollow Molding Machinery category and was also honored with the inaugural Green Machinery Award.

2022● At TaipeiPLAS, CHUMPOWER unveiled the SS10-rPET one-stage injection stretch blow molding machine, capable of producing bottles from 100% rPET. The machine won the Excellence Award in the Plastic Hollow Molding Machinery category and was also honored with the inaugural Green Machinery Award.

● Solar panels were installed at the Wuri headquarters to increase the utilization of renewable energy. -

2021● The High-speed Stretch PET Blow Molding Machine CPSB-LSS8 has been honored with the Taiwan Excellence Award 2021.

2021● The High-speed Stretch PET Blow Molding Machine CPSB-LSS8 has been honored with the Taiwan Excellence Award 2021.

● The new CHUMPOWER headquarters in Wuri has been officially inaugurated.

-

2020● COVID-19 has quickly spreads across the world, CHUMPOWER put into production of Melt-blown non-woven fabric production line, Melt-blown non-woven fabric and cloud face mask machine.

2020● COVID-19 has quickly spreads across the world, CHUMPOWER put into production of Melt-blown non-woven fabric production line, Melt-blown non-woven fabric and cloud face mask machine.

● Signed MOU of “ Intelligent system solution for blow molding production line” with BECKHOFF.

-

2019● The new facility of CHUMPOWER's Chinese subsidiary, QUINKO (Fujian) Machinery Industry Co., Ltd., has been completed.

2019● The new facility of CHUMPOWER's Chinese subsidiary, QUINKO (Fujian) Machinery Industry Co., Ltd., has been completed.

-

2018● Authorized to public offering by Taipei Exchange in 2018.

2018● Authorized to public offering by Taipei Exchange in 2018.

● With support from the Industrial Development Bureau, MOEA, and the Smart Machinery Office, CHUMPOWER implemented a smart manufacturing system and hosted a Smart Manufacturing Open Day in July.

● At the Taipeiplas, CHUMPOWER unveiled the then world’s fastest linear stretch blow molding machine, CPSB-LSS8, which received an Second Prize in the Plastic Hollow Molding category. The BottleViewer e-Manufacturing Real-time Execution System was awarded one of the competition’s top three honors – the Smart Machinery Award.

● Implemented the SAP ERP system.

● The CHUMPOWER brand received the Second Taiwan Outstanding Trademark Award - Excellence Trademark Distinction.

-

2016Jingke Factory Completion.

2016Jingke Factory Completion. -

2015Through the constantly growth, CHUMPOWER became a major corporation with over 85 thousand square meters of production base in the Greater China region, amount of capital NT$ 250 million, and a staff force of over 500 employees.

2015Through the constantly growth, CHUMPOWER became a major corporation with over 85 thousand square meters of production base in the Greater China region, amount of capital NT$ 250 million, and a staff force of over 500 employees. -

2012Obtained 6000 square meters in Taichung City Precision Machinery Technological Park for the construction.

2012Obtained 6000 square meters in Taichung City Precision Machinery Technological Park for the construction.

-

2011Established the Jia-Xing Plant; production base in Greater China region exceeds 50 thousand square meters.

2011Established the Jia-Xing Plant; production base in Greater China region exceeds 50 thousand square meters.

-

2010Relocation of plants in Taiwan to the new Wuri Plant in Taichung that has over 17,500 square meters.

2010Relocation of plants in Taiwan to the new Wuri Plant in Taichung that has over 17,500 square meters. -

2006● Employee strength in Greater China and Thailand has exceeded 200, amount of capital reached to NT$ 110 million. Entered strategic alliance with major US companies, and began providing comprehensive services for whole PET production lines.

2006● Employee strength in Greater China and Thailand has exceeded 200, amount of capital reached to NT$ 110 million. Entered strategic alliance with major US companies, and began providing comprehensive services for whole PET production lines.

● Began introducing titanium alloy materials into accessory products. -

2005Establishment of Thailand branch

2005Establishment of Thailand branch -

2003CHUMPOWER tool chuck products entered medical markets.

2003CHUMPOWER tool chuck products entered medical markets. -

2002Fully automatic PP blow molding machine was launched.

2002Fully automatic PP blow molding machine was launched. -

2001During the “Taipei International Plastics & Rubber Industry Show” (Taipei Plas), the new CPSB-2000W model stood out among the rest, allowing CHUMPOWER to won the excellence award of the highest honor again.

2001During the “Taipei International Plastics & Rubber Industry Show” (Taipei Plas), the new CPSB-2000W model stood out among the rest, allowing CHUMPOWER to won the excellence award of the highest honor again.

-

2000● Qualified to bear the Taiwan Excellence Award, and the Rising Star Award issued to small and medium enterprises by Ministry of Economic Affairs.

2000● Qualified to bear the Taiwan Excellence Award, and the Rising Star Award issued to small and medium enterprises by Ministry of Economic Affairs.

● In the same year, the accessory department authorized the patent to the U.S. company JACOBS; becoming long-term cooperation partners.

-

1998Obtained the European CE Certification

1998Obtained the European CE Certification -

1997

1997 -

1996The leading-technology CHUMPOWER developed the second-generation PET stretch blow molding machine, won the highest honor of the “Precision Plastics & Rubber Machinery”.

1996The leading-technology CHUMPOWER developed the second-generation PET stretch blow molding machine, won the highest honor of the “Precision Plastics & Rubber Machinery”. -

1994First PET stretch blow molding machine was launched in Taiwan.

1994First PET stretch blow molding machine was launched in Taiwan. -

1993Obtained the U.S. Lockheed Certification and became a cooperative production partner. In the same year, Quinko Fujian Machinery Industrial Co., Ltd. was established in mainland China.

1993Obtained the U.S. Lockheed Certification and became a cooperative production partner. In the same year, Quinko Fujian Machinery Industrial Co., Ltd. was established in mainland China. -

1992Completed technology transfer with Industrial Technology Research Institute and developed the first laser-cutting machine in Taiwan.

1992Completed technology transfer with Industrial Technology Research Institute and developed the first laser-cutting machine in Taiwan.

-

1985In response to the industrial upgrading policy, it became the largest drill chuck manufacturing factory in Taiwan at the time.

-

1981CHUMPOWER Machinery Corp. was established and had capital of NT$ 5 million.