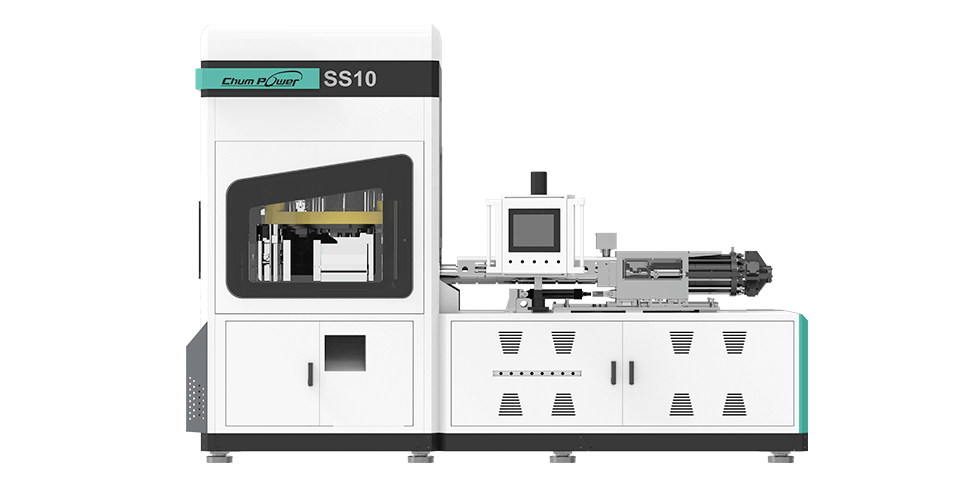

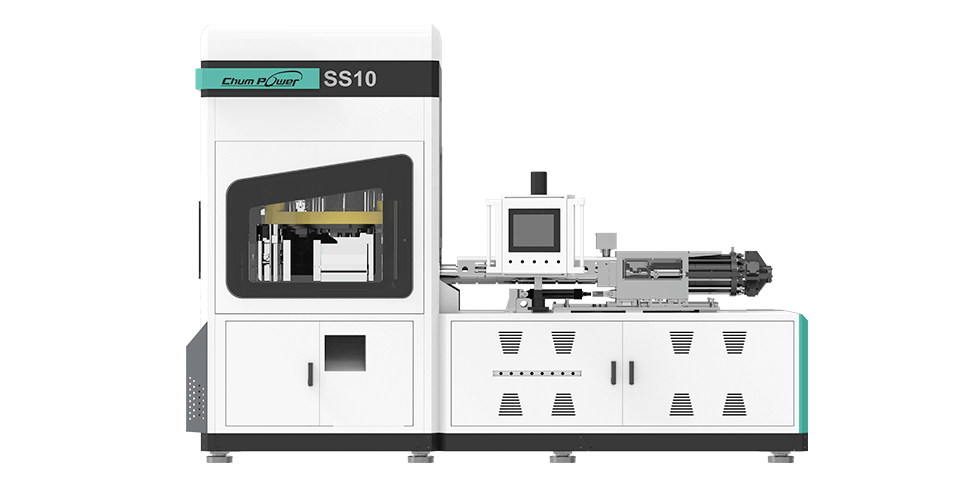

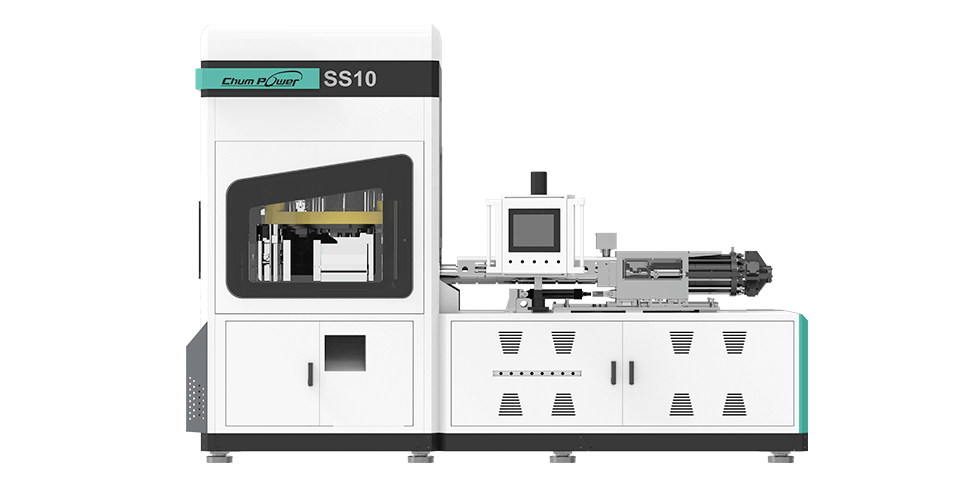

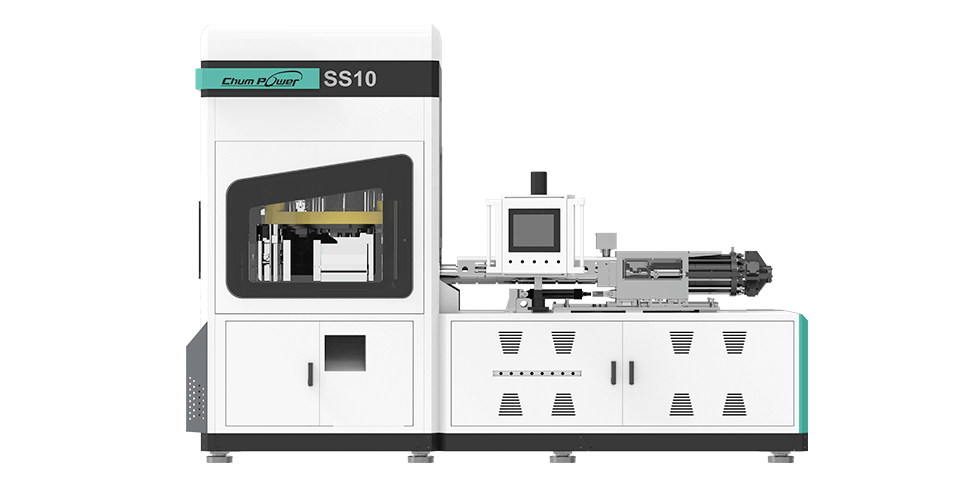

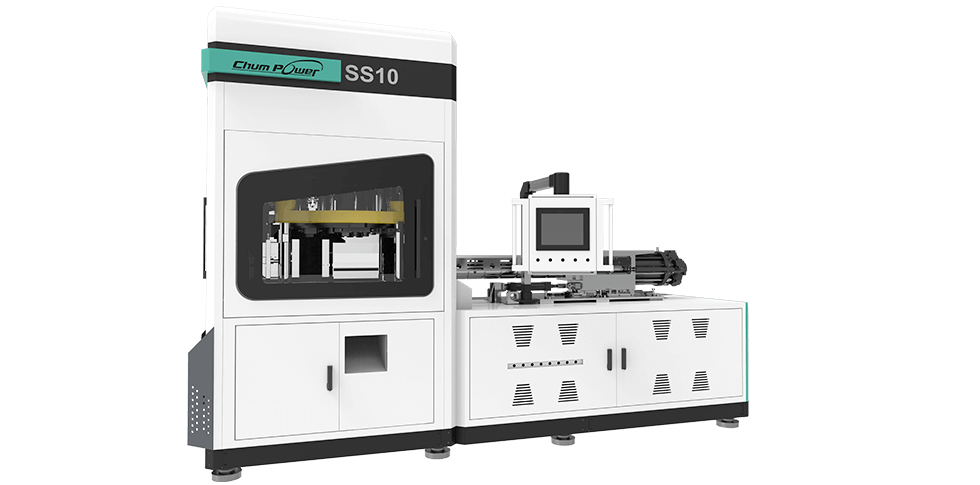

SS10 Series

Single-stage Injection Stretch Blow Molding Machine

Max.capacity

10ML-2.5L

Cavity

1~8

Single-stage PET bottle blowing machine

- Specially designed and developed for small volume diversified production and special bottle designs.

- Finished products with glossy, complete, and untarnished appearances. Suitable for high-priced and high quality bottle production.

- Fulfilling all bottle requirements with just one machine.

- Removal of the two-stage heating, can save up to 40% electricity.

FEATURES

-01_vpic.jpg)

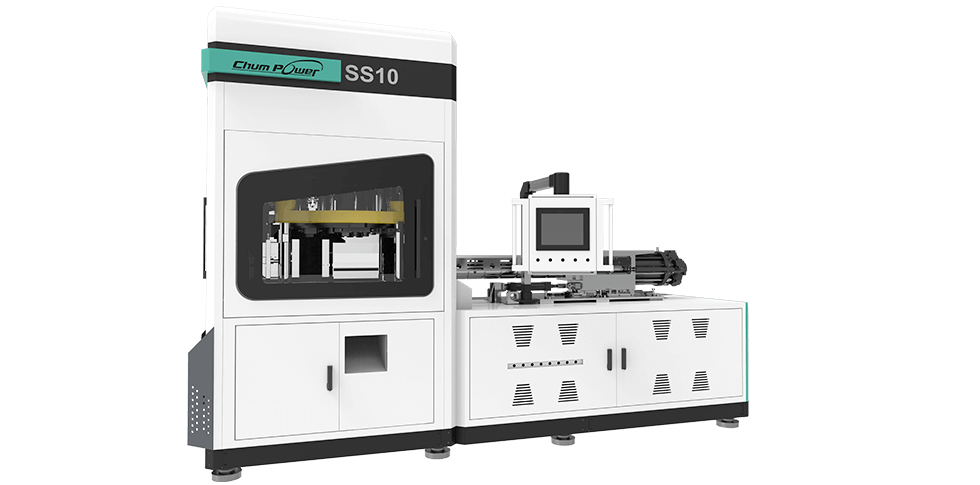

Production Flexibility

- Depending on neck size, the machine can process bottle size from 10 ccs (8 cavities) to 2.5 L (single cavity), which offers great production flexibility with various resin types such as PET, PET-G, TRITAN, and rPET. Fulfilling all bottle requirements with just one machine.

Wide Product Range

- Specially designed and developed for small volume diversified production and special bottle designs. Regardless of medicine bottles, cosmetic bottles, perfume bottles, detergent bottles, baby bottles, or special design bottles, this machine can fulfill all your production needs.

High-quality Assurance

- In single stage process, preform injection and bottle blowing are done in one machine, as the neck is handled by the die throughout the entire process and blow molding is to ensure the preforms do not come into contact with other objects during transportation, thus producing finished products with glossy, complete, and untarnished appearances. Suitable for high-priced and high-quality bottle production.

Innovative Design for Upgraded Quality

- The standard hot runner for SS10 is the industry standard thermal gate type; however hot runner with valve gate type is also available for higher preform gate finishing and wider processing window. An independent blow molding system and a smart temperature control system to ensure the improved quality of the finished products.

General Mold System

- SS10 applies the general mold system, which applies to one sectional mold of other brands so that its original mold could be directly connected. Launching SS10 could not only shorten the time for starting production but also reduce the production cost.

Economic and Energy Saving Production Method

- Without the need to outsource preforms or for additional capital investment in injection machinery purchase, single stage process provides the advantages of lower operational cost and occupies less floor space (No need for preform storage). Since this process does not require secondary heating, With the help of servo driven injection system coupled with a hybrid hydraulic system, CPSB-SS10 is able to save up to 40% in energy consumption while improving the overall output by 25%.