Complete Maintenance Guide for Stretch Blow Molding Machines|Extend Lifespan & Ensure Stable Production

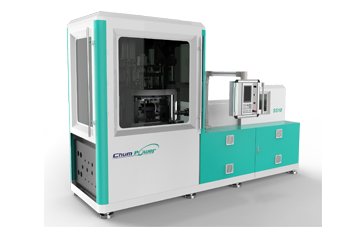

Stretch blow molding machines play a crucial role in producing high-quality PET bottles for bottled water, beverages, personal care, and household products.

Without proper maintenance and preventive planning, these machines are prone to frequent malfunctions, inconsistent bottle quality, or even production downtime.

Conversely, with regular maintenance, systematic inspection of key components, and preventive maintenance practices, you can significantly extend the machine’s lifespan and ensure long-term, stable operation.

This article outlines:

- Daily maintenance essentials

- Key component upkeep

- Preventive maintenance best practices

Daily Maintenance — The Foundation of Stable Operation

-

Cleaning and Foreign Object Inspection

- Clean the machine’s surface and internal components regularly to prevent dust, debris, or oil buildup from affecting performance.

- Check for foreign objects in moving parts, pneumatic lines, and heating zones to ensure smooth and uninterrupted operation.

-

Lubrication and Mechanical Maintenance

- Lubricate key components—such as guide rails, bearings, and columns—at regular intervals to minimize friction and wear.

- Use the recommended lubricants and replenish them according to operational frequency to maintain smooth mechanical motion.

-

Air Pressure and Cooling System Check

- Verify that high-pressure, low-pressure, and pre-blow pressures remain within the specified range to prevent quality issues.

- Inspect chiller water temperature and pressure to ensure the cooling system operates efficiently and prevents mold overheating.

Tip: If pressure fluctuations or reduced cooling efficiency occur, check for leaks, blockages, or insufficient chiller flow immediately.

Inspection and Maintenance of Key Components

-

Heating System (Lamps & Temperature Control Modules)

- Ensure all heating lamps output stable power. Uneven heating or non-functional zones indicate the need for replacement.

- Regularly monitor the preform heating profile to maintain uniform softening and optimal bottle forming conditions.

-

Mold Maintenance

- Clean mold cooling channels regularly to stabilize temperature and ensure consistent bottle quality.

- Check for surface wear, scaling, or contamination that may cause dimensional inaccuracies.

-

Sensors and Electrical Control Systems

- Inspect photoelectric sensors and proximity switches for proper sensitivity to prevent false signals or unplanned stoppages.

- Periodically test PLC and HMI displays to ensure data is accurate and error signals are correctly transmitted.

Tip: If sensors malfunction, clean lenses and check alignment before replacement — dust or mispositioning often cause detection errors.

Preventive Maintenance — Minimizing Unexpected Downtime

-

Scheduled Maintenance Plan

- Establish weekly, monthly, and semi-annual maintenance schedules to cover all key components.

- Keep daily inspection records to track machine performance trends and detect anomalies early.

-

Regular Replacement of Wear Parts

- Replace seals, cams, bearings, and linear guide blocks periodically to maintain mechanical stability and reduce failure risk.

- Keep spare parts on hand to avoid extended downtime during replacements.

-

Proper Installation and Assembly Sequence

- Follow the correct replacement order to avoid misalignment or jamming during assembly.

- Tighten all screws to their specified torque values to prevent vibration, abnormal wear, or component damage.

Tip: If frequent breakdowns occur after long-term use, conduct a full inspection and system-level overhaul to restore performance.

Conclusion — How to Extend the Lifespan of Your Stretch Blow Molding Machine

To keep your stretch blow molding machine operating at its best, focus on these three pillars:

| Category | Key Practices | Benefits |

|---|---|---|

| Daily Maintenance | Cleaning, lubrication, pressure & cooling checks | Stable and smooth machine operation |

| Key Component Upkeep | Heating, mold, and sensor system inspections | Consistent quality and reliability |

| Preventive Maintenance | Scheduled servicing and part replacements | Extended lifespan and reduced downtime |

By applying these structured maintenance strategies, you can enhance productivity, reduce repair costs, and maintain consistent PET bottle quality.

For further assistance, consult your equipment manual or contact CHUMPOWER’s technical service team to ensure your system stays in top condition.

FAQ|Stretch Blow Molding Machine Maintenance

Q1: How often should I perform maintenance?

A1: Conduct weekly visual checks, monthly lubrication and cleaning, and a full inspection every 6 months for optimal performance.

Q2: What are the most common wear parts?

A2: Seals, bearings, guide rails, cams, and heating lamps—these should be replaced periodically based on runtime hours.

Q3: How can I reduce unexpected breakdowns?

A3: Implement a preventive maintenance plan, monitor air pressure and cooling performance, and replace parts before they fail.

Q4: Who should perform equipment maintenance?

A4: Operators can handle daily cleaning and visual inspections, but electrical and pneumatic systems should be serviced by trained technicians.

Pro Tip:

Integrating your stretch blow molding machine with digital monitoring tools—like CHUMPOWER’s BottleViewersystem—allows real-time tracking of production, energy use, and machine health for smarter preventive maintenance.