CHUMPOWER's Two-Stage Blow Molding Machines: A Sustainable Boost for the Beverage Industry

As the bottled beverage market continues to thrive, Taiwan's largest PET blow molding equipment manufacturer, Chumpower Industrial, is showcasing its expertise with over 40 years of experience and a presence over 115 countries. During the TAIPEI PACK 2025 , Chumpower highlights its two-stage stretch blow molding machine series—the L Series, W/L Series, and Phoenix Series—offering comprehensive solutions tailored to the diverse needs of the bottled water and beverage market.

L Series: High Output × Energy Efficiency × rPET Ready

Designed for medium-to-high output and superior energy efficiency, the L Series is ideal for bottled water, tea, juice, and other fast-moving consumer goods. It boasts a total output capacity of up to 24,000 bottles per hour and can be integrated with filling machines to form a "blow-fill-cap" production line. Supporting up to 20% bottle weight reduction, the system includes gas recovery and optimized heating modules that enhance energy efficiency by over 30%. The L Series also supports 100% rPET processing, helping brands adopt low-carbon, sustainable packaging.

Chumpower's L Series PET blow molding machines are widely acclaimed by industries worldwide.

W/L Series: Wide Neck × Special Shapes × Customizable Flexibility

Engineered for large-capacity, wide-neck, and special-shaped bottles, the W/L Series is suitable for packaging such as bottled water, tea, health drinks, cleaning products, and handled edible oil bottles. Its modular structure allows easy maintenance and expansion, while the dual-robot arm system and side-heating technology ensure consistent product quality. With its highly flexible configurations, the W/L Series is the ideal solution for wide-neck bottle, irregularly shaped and large-volume containers.

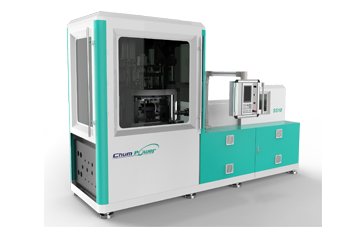

Phoenix Series: High Value × Easy Operation × Ideal for Small-to-Medium Production

Targeting small-to-medium production needs, the Phoenix Series offers a cost-effective solution with 2 to 6 cavities. It accommodates a wide range of applications including mineral water, carbonated drinks, juice, tea, and condiments. With a compact design and user-friendly operation, it is especially well-suited for startups and businesses seeking cost efficiency.

Chumpower provides comprehensive pre-sales technical consulting and production line planning, supporting customers from bottle design and production line layout to turnkey plant solutions. Backed by a global technical support network, Chumpower ensures fast implementation and stable production, minimizing risks and time-to-market.

With its extensive PET blow molding solutions covering various applications—from high-output machines and specialty bottles to automated systems—Chumpower serves the beverage, food, personal care, cosmetics, and healthcare industries. Moving forward, the company remains committed to its product philosophy of "energy-saving, high-efficiency, and flexible production," helping customers enhance packaging differentiation and create sustainable value.