Advantages of servo system applied in PET stretch blow molding machine

Servo System

A servo system is an automatic control system that can output the controlled data of an object’s location, orientation, and status, and change these data along with the input target (or setting). Its main task is to follow the requirements of the control commands to amplify, change and regulate output power; enable the torque, speed, and position outputted from the driver to be controlled in a very flexible and convenient matter.

The servo system firstly was originally applied to the boat’s auto-pilot, canon control, and commanding meters; it then was extended to many fields, particularly the auto-lathe, antenna-location control, and missile and spacecraft guiding, etc.

Advantages of Servo System

The reason for using a servo system mainly is to control large power loading by small-power commanding signals; under no mechanical linking state, use the input axle to control remote output to fulfill simultaneous and remote transmission; as well as have the mechanical distance output tracks down the telecommunication signal precisely, such as the recording and indication instruments/gauges, etc. So far the servo system is used in the fields of a wide variety of, such as machine tools, special machines, electric-drive vehicles, and robots, etc.

Blow Molding Machine Servo Controller

The servo system can simultaneously control multiple axles by means of an electronic cam; the connection of actions from different axles needs not to go through external inspection or other program operation, which can reduce the reacting time, elevate blow molding speed and obtain high production capacity. The Servo motor has a smaller size and higher power-transmission efficiency, allowing downsizing the installation space while working with a ball screw and timing belt; making the PET stretch blow molding machine take smaller space, and thus client can have bigger space for other usage.

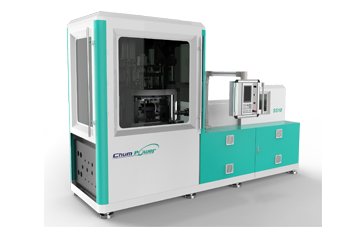

Servo Control System PET Bottle Blowing Machine Manufacturers

The CHUMPOWER PET stretch blow molding machines also apply the servo system. It can directly activate the movement, control the output power scale and decide on moving speed to reduce energy loss. The servo system also can adjust the speed-varying section, location, and speed and largely reduces vibration and noise made from mechanism operation; and increases the lifetime of PET stretch blow molding machine parts.

If you need a servo system blowing machine, welcome to contact us!

* Servo system (source: baike.baidu.com)